ELLABELL, Ga. (AP) — Hyundai celebrated the opening of its new $7.6 billion electric vehicle factory in Georgia on Wednesday by announcing plans to expand its production capacity by two-thirds to a total of 500,000 vehicles per year.

The news came as President Donald Trump announced 25% tariffs on auto imports at the White House. Hyundai will be spared from those tariffs on its U.S.-made vehicles. Trump praised the South Korean automaker on Monday, saying its American investments are “a clear demonstration that tariffs very strongly work.”

Hyundai began producing EVs just shy of six months ago at its sprawling manufacturing plant in southeast Georgia. More than 1,200 people are working there.

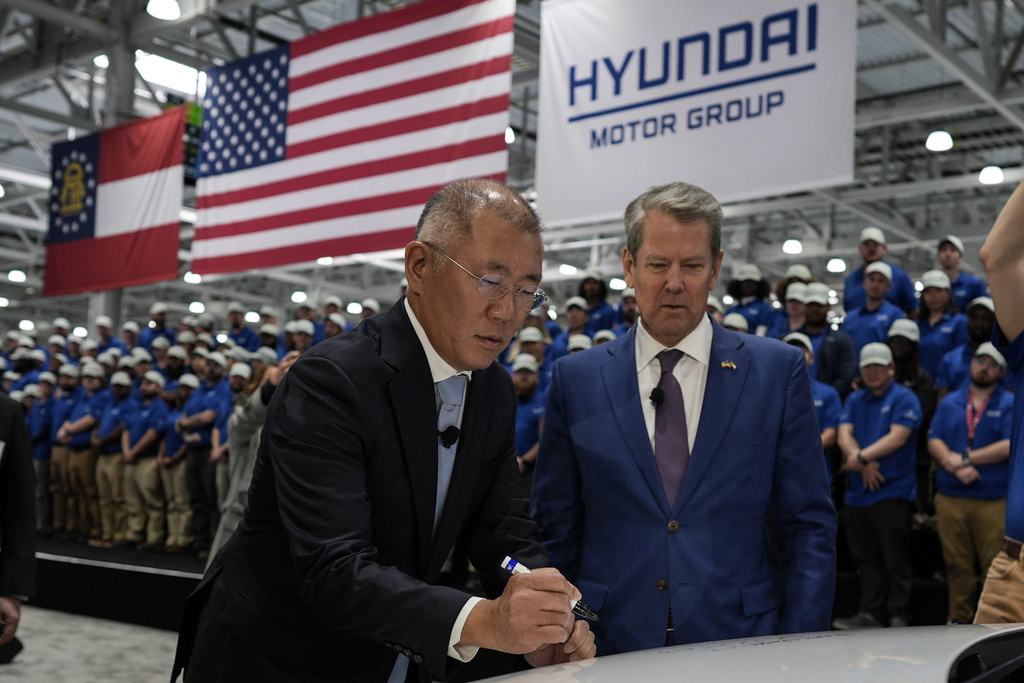

With employees in blue shirts filling bleachers behind him Wednesday, Hyundai Motor Group Executive Chairman Euisun Chung said the company plans to increase the plant's capacity from 300,000 vehicles per year to 500,000. He said it shows Hyundai has come to Georgia “to stay, to invest and to grow.”

“Standing here today, I can say I have never been more confident about building the future of mobility with America, in America," Chung said.

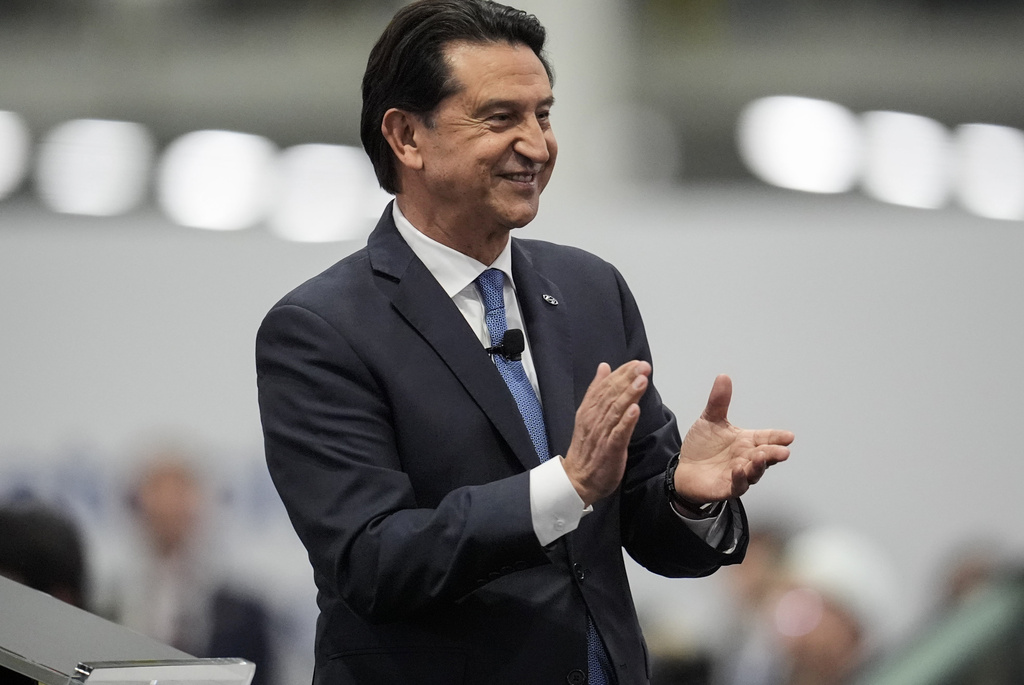

Hyundai Motor Company CEO Jose Munoz said the Georgia expansion was “like building a new plant.”

Munoz stated to reporters, “This plant could not have arrived at a more opportune moment than right now,” adding that “all the vehicles produced here will undoubtedly be exempt from any tariffs.”

On Wednesday, Hyundai workers joined forces with numerous robots on the assembly line. These machines stamped steel sheets into components like fenders and door panels, welded and painted car bodies, and even parked completed vehicles for their final inspection.

The sprawling plant covering 3,000 acres produces a completed vehicle approximately every sixty seconds. At present, its workforce of 1,200 employees is manufacturing two different electric sport utility vehicles. Ioniq 5 And the bigger Ioniq 9 scheduled for launch this spring. Additionally, Hyundai intends for the facility to manufacture hybrid models, with Munoz forecasting they will ultimately account for one-third of the production at the site.

The newly announced Georgia expansion is part of $21 billion in U.S. investments over the next three years that Hyundai announced at the White House with Trump on Monday. They also include a $5.8 billion steel mill in Louisiana to produce auto parts for Hyundai's assembly plants in Georgia and Alabama.

Chung expressed to Trump at the White House, "We are genuinely proud to stand alongside you and thrilled to construct our future together."

Prior to the announcement of the expansion, Hyundai stated its intention to have a workforce of 8,500 employees at the Bryan County location, situated approximately 50 miles (80 kilometers) west of Savannah. The two companies collaborating on battery production at this facility are projected to contribute an additional 3,500 jobs.

Hyundai has not specified the number of extra employees required to boost production by 200,000 vehicles annually.

In the first six months of 2024, the Ioniq 5 ranked as the second most popular electric vehicle in America, excluding those produced by top manufacturer Tesla.

Hyundai managed to begin producing electric vehicles in Georgia in under two years following the commencement of construction in autumn 2022. This marked the biggest economic development initiative the state had ever experienced, accompanied by an impressive investment. $2.1 billion worth of tax incentives And various encouragements offered by state and local governments.

EVs made up 8.1% of new car sales in the U.S. the previous year, an increase from 7.9% in 2023, as reported by Motorintelligence.com.